How does a steam trap work? How steam traps work

What is a steam trap? A steam trap is one of the most important components in industrial steam systems. The way a steam trap works is that it helps to maintain steam in the lines and drain condensate through a control valve, helping to ensure optimal performance and increase safety of steam systems. The way a steam trap works can also vary.Because there are different types of steam traps, we will explain them to you in the form of a table below, according to the use of each.

| Types of steam traps | ,how steam traps work | ,uses of each type |

| Mechanical steam trap | ,using float to control condensate level and valve | ,boilers and heat exchangers with high condensate volume |

| Thermostatic steam trap | uses temperature changes to open and close the valve | of heating systems as the condensate temperature drops. |

| Dynamic steam trap | :Using the dynamic force of steam and condensate with a moving disk | .Steam lines with high pressure and temperature and rapid changes. |

Types of steam traps and how they work

Steam traps have different uses, wherever there is steam, some of it will condense in the pipes, condensers, tanks and other equipment. The presence of condensate or liquid water in the steam path disrupts the proper and optimal functioning of the system. For this reason, its removal is essential.Steam should also not be allowed to escape, as regenerating it is costly and uneconomical. Essentially, a steam trap is a device that only removes condensate from a system that must contain steam.

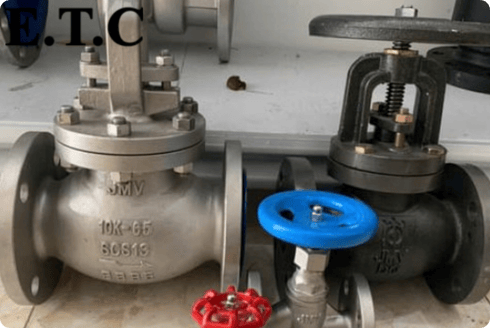

There are various types of steam traps. Types of steam traps include:

- Mechanical Steam Trap: A steam trap, or mechanical steam trap, uses a float to open and close the steam pressure relief valve. This float operates by changing the level of condensate inside the steam trap.

- Thermostatic Steam Trap: In a thermostatic steam trap, as the temperature decreases, the valve opens and condensate is removed from the lines. Also, as the temperature increases, the valve closes.

- Dynamic Steam Trap: This type of steam trap moves with the help of a disc as steam or condensate enters. Also, as the pressure of steam and condensate changes, the disc moves up and down, opening and closing the pressure reducing valve.

Mechanical steam trap

In this type of steam trap, the orifice is controlled by a small conical or ball valve.The said cone or ball is located on a lever that moves up and down with the help of the difference in density of water and steam. When there is water inside the steam trap tank, the handle moves up and the valve opens. Finally, due to this function, the condensate comes out and when the condensate comes out, the valve also closes.

Thermostatic steam trap

The operation of a thermostatic steam trap is controlled by a thermostatic valve that is sensitive to the temperature of the fluid, and as the temperature decreases and increases, the steam needle valve opens and closes. Thermostatic valves are designed in such a way that when the fluid reaches them at a low temperature, they contract and open the exit. Also, when the fluid reaches them at a high temperature, they expand and do not allow it to exit.

Dynamic steam trap

In a dynamic steam trap, there is only one moving part. This part is a small disc that is placed on the steam trap seat and above the inlet and outlet orifices. The way a dynamic steam trap works is that when liquid reaches the steam trap, it simply lifts the disc and enters the upper chamber of the steam trap. It is finally discharged through the outlet orifice.

Important points in choosing and using a steam trap

It is very important to know and pay attention to some points before choosing and using a steam trap. Because choosing the right steam trap can prevent common problems with steam systems and save energy. It is also worth noting that periodic maintenance and service play a significant role in the performance of a steam trap.Important points in choosing and using a steam trap are as follows:

- Pay attention to the type of steam trap according to system conditions such as pressure, temperature, and volume.

- Regular periodic service and maintenance of the steam trap for proper and optimal performance

- Regular pressure and temperature measurements to prevent system failure and wear and tear

How does a steam trap work?

In the following article, we are going to show you how “steam traps work”, step by step. This will help you have a better understanding of the steam trap and know exactly what stage you are in when using it. Lack of awareness leads to damage to components and waste of energy.

The steps of the steam trap operation are as follows:

- Steam and condensation ingress

- Fluid type detection

- Steam storage and condensate drainage

- Automatic exit closure

- Repeat the cycle automatically and continuously

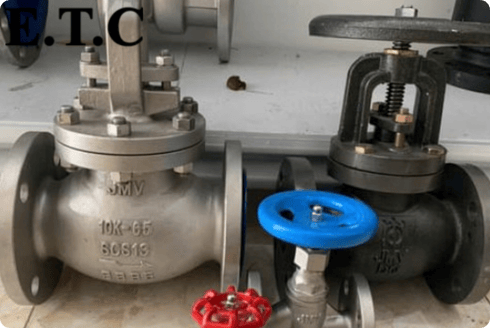

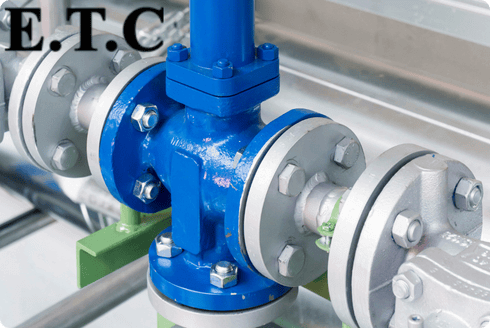

Suitable location for installing a steam trap

In addition to being careful in selecting a steam trap and how to use it, special attention should be paid to the location of the steam trap. It is worth noting that the “location of the steam trap” has a direct impact on the efficiency and performance of steam systems. Choosing the right location for the steam trap will help you prevent water backflow, pipe corrosion, and reduced system efficiency and effectiveness.

The proper installation location for a steam trap is as follows:

- Downstream of the steam consumer: The steam trap should be installed downstream of the consumer, as this will cause the condensate formed to flow to the trap immediately after the temperature drops, and its accumulation in the system will be reduced to the desired minimum.

- The lowest part of the system: Installing a steam trap at the lowest part of the system prevents condensation from accumulating in different corners of the system. It also prevents the occurrence of check shock, which can cause serious damage to the system.

- Before the shut-off valve: A steam trap is usually installed between two valves. One valve is for shutting off the steam flow and the other is for manual control or drain. This type of installation allows the system to be serviced or repaired without shutting down the entire system.

There are three types of steam traps: mechanical, thermostatic, and dynamic.

A steam trap essentially allows condensate to escape from the pipelines while retaining the gas.

Yes. The installation location has a significant impact on the optimal performance of the system and the prevention of energy waste.