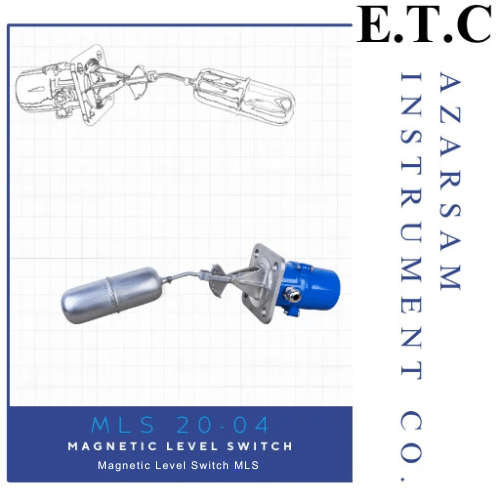

Magnetic Level Switch MLS 20-06

The MLS 20-06 type magnetic level switch is one of the most widely used and economical equipment in this field, designed to monitor the level of a variety of liquids, from plain water to challenging fluids.

Contact us for pricing and expert advice.

MLS 20-06 Magnetic Level Switch: Industrial Tank Level Control

The MLS 20-06 type level switch is one of the most widely used and economical equipment in this field, designed to monitor the level of a variety of liquids, from plain water to challenging fluids.

Technical features of the MLS 20-06 level switch

This mechanical level switch is built to perform in the harshest industrial conditions:

- Wide pressure range: Ability to operate at nominal pressures of PN16 to PN40.

- High temperature tolerance: Stable performance at operating temperatures up to 150°C (302°F).

- Installation flexibility: Available in two models: gear connection and flange connection for compatibility with a variety of existing systems.

- Robust construction: Simple, mechanical design that reduces the need for complex maintenance.

Key applications of the MLS 20-06 level switch

The capabilities of this device make it an ideal choice for dozens of different uses:

- Water supply systems: Level control of water storage tanks and booster pumps.

- Deaerators: Prevent excessive lowering or raising of the water level in deaerators.

- Fuel management: Control the level in fuel tanks (diesel, fuel oil) and send full or empty alarms.

- Condensate tanks: Protect condensate pumps and prevent overflow into collection tanks.

- Pressurized sources: Use in small boilers, condensate tanks and other pressurized vessels.

- Chemical industries: Use in acid tanks and water and wastewater treatment plants (depending on the body material).

Why choose MLS 20-06 for level control?

The reasons for the popularity of this level switch among engineers and industrial buyers include:

- Non-dependence on electricity: Due to its purely mechanical nature, it continues to work in the event of a power outage.

- Easy installation and setup: It does not have the complexities of electronic systems.

- Affordable price: Compared to fully automatic systems, it has lower initial and maintenance costs.

- High reliability: With minimal moving parts, it offers a long operating life.

Important note: To make the right choice, always pay attention to the material of the body and float according to the type of fluid (e.g. acid).

Electromagnetic level switch operating mechanism: accuracy and reliability in level control

Using a physical principle, electromagnetic level switches have become one of the most reliable devices for controlling liquid levels in various industries. But how does this device work?

The basics: from fluid motion to electric steering

The operation of this level switch can be summarized in a few simple and efficient steps:

- Float (ball) movement: A float (ball) mounted on a vertical rod moves up and down in line with the liquid level. The float is essentially the eye of the device, tracking changes in the level.

- Sending a command: As the float moves and reaches predetermined levels (for example, the tank fill or empty point), one or more internal sensors are triggered.

- Equipment Control: These sensors generate an ON/OFF command signal. This command can be sent directly or through a control panel to equipment such as electric pumps, solenoid valves, and warning lights to automatically perform the desired operation (such as turning the pump on or off).

Key benefits and features of this level switch

- Completely stainless steel parts: All parts in contact with the liquid are made of stainless steel, which ensures long life, corrosion resistance, and compatibility with a wide range of liquids, even acids.

- Excellent waterproofing: The body of the device is completely sealed against moisture and water penetration, ensuring its reliability in humid environments.

- Flexibility in installation: This equipment can be installed in two ways: top (on the tank) and side (on the tank wall), which allows for use in different types of tanks.

- Expandability and customization:

- Ability to add more sensors to create multi-stage alarm systems.

- Possibility of using multiple floats on a rod to increase the system reliability factor or create more complex control logics (such as controlling one pump as the main and the other as a backup)

Possibility of using multiple floats on a rod to increase the system reliability factor or create more complex control logics (such as controlling one pump as the main and the other as a backup)

Proper installation of the MLS 20-06 level switch is key to achieving maximum accuracy and longevity. The device can be flexibly installed in several ways, depending on the type of tank you have.

Main installation methods

1. Installation from above the tank (Top Mounting)

This is the most common installation method used for underground (buried) tanks as well as surface tanks. In this method, the device is simply mounted on the top opening of the tank via a flange or spigot connection. This method provides easy access for maintenance.

2. Installation in high-altitude tanks (use of restraint)

When the tank height exceeds 1.5 m (1500 mm), hydrodynamic forces and fluid fluctuations can exert significant pressure on the sensor rod and cause damage. To prevent this problem, the use of a stabilizer (or bottom guide) at the bottom of the tank is strongly recommended. This prevents excessive bending and vibration of the rod and ensures measurement accuracy.

3. Side Mounting with Chamber

In cases where top installation is not possible, the device can be mounted on the side wall of the tank. For this purpose, the level switch is placed inside a chamber (separator or bypass chamber), which is then connected to the side of the tank through two nozzles. Using a chamber not only facilitates installation but also protects the sensor from direct liquid turbulence and makes it accessible for service and calibration.

Key tips for proper installation and extending the life of the device:

- Buried tanks: For these tanks, top-mounting is the only option available. Ensure complete sealing of the connection.

- Tall tanks: Using a restraint on the bottom of tanks with a height of more than 1.5 meters is a requirement, not an option.

- Side mounting: Using a chamber for side mounting is the best way to protect the device and ease maintenance.

Technical specifications and materials:

PressureTemperatureLengthProtectionpower & current output of CP22 panelsupply of CP22 panelMaterial (Ex d client order)

| Nominal | PN16 / 40 | |

| Working | -10 …+150 ˚C | |

| Makeable | 300mm … 2000mm | |

| Ingress | IP65 | |

| The lowest density | Min. Density |

Ti 0.5/ S.S 0.85 |

| The highest viscosity | Max Viscosity |

400 cSt |

| Output | 3A 220VAC | |

| Power | 220V AC | |

| Box | AL | |

| Ball material | Ball Material |

SS304/316 /Ti |

| Flange material and other fluid-related accessories | Flange & other parts inside liquid |

SS304/316 |

| Connection type and size | Size & Type of connection |

Flanged or Screwed (DN50,2″#150/300) |

Reviews

There are no reviews yet.