Pear Level Switch | PLS 20-10

The PLS 20-10 pear level switch (with a pressure rating of 4 bar and an operating temperature of 50°C | 122°F) is a precise solution for automatic liquid level control at a desired installation height. This industrial device is designed with stable performance in challenging environments.

Contact us for pricing and expert advice.

Level Switch PLS 20-10 | Liquid level control in industrial tanks and wells

The PLS 20-10 pear level switch (with a pressure rating of 4 bar and an operating temperature of 50°C) is a precise solution for automatic control of liquid levels at the desired installation height. This industrial equipment with stable performance in acidic and corrosive environments is an ideal choice for:

- Drinking and industrial water storage tanks

- Acid and chemical tanks

- Water and sewage pumping stations

- Agricultural and drinking water wells

- Urban and industrial sewage systems

- Underground concrete tanks and air tanks.

Key benefits of PLS 20-10:

✅ Easy installation in variable tank heights

✅ Reliable operation under 4 bar pressure

✅ Corrosion resistance in contact with acids and corrosive fluids

✅ No need for frequent calibration

✅ Compatibility with a wide range of liquids (from water to viscous fluids)

Specialized Applications:

This level switch is specifically used in infrastructure projects such as water treatment plants, water distribution networks, pressurized irrigation systems and chemical industry units. Its robust design ensures reduced measurement errors and increased operational safety in sensitive environments.

Technical highlights:

▫️ Temperature range: 0 to 50°C

▫️ Output: SPDT

▫️ Body material: Polymer

▫️ Protection rating: IP66 (dust and splash resistant)

Optimal title: PLS 20-10 level switch operating mechanism | Electromechanical level control

Optimized text:

Intelligent operation system

The PLS 20-10 level switch electromechanically controls the level of liquids through a simple mechanism and without the need for an external power source. The core of this device’s operation is based on converting mechanical motion into an electrical signal.

Step-by-step operation steps:

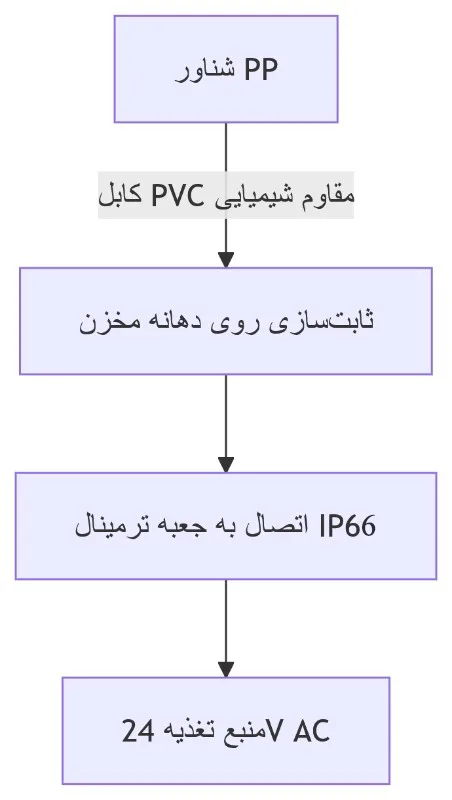

1- Suspended installation: The device is suspended in the liquid up to a depth of 40 meters using a chemically resistant PP float and a special PVC cable.

2- Level detection:

-

- When the liquid reaches the installation height, the float deviates 90 degrees by buoyancy force.

- This change in angle displaces the internal metal ball from its initial position on the microswitch.

3- Send command:

-

- Moving the ball activates the SPDT contacts of the microswitch.

- ON/OFF signals to control equipment such as:

- Water and sewage pumps

- Warning systems

- Automatic control valves are produced.

4- Return to the initial position: As the liquid level decreases, the float returns to the vertical position and the ball returns to the initial position on the microswitch, and the circuit is interrupted.

Unique benefits:

- No need for calibration: self-leveling design.

- Near-zero maintenance: No moving parts to wear out.

- Instantaneous response: Fast response time.

Sensitive applications:

This reliable mechanism is used in critical projects such as:

- Chemical tank leak alarm systems

- Level control in deep agricultural wells

- Preventing dry running of sewage pumps

- High viscosity media (industrial oils)

Level switch mechanism PLS 20-10 | Energy-free level control at 40 meters depth

Performance core

Level switch The PLS 20-10 revolutionizes the level control industry by utilizing electromechanical technology (no external power source required). The system operates based on Archimedes’ principle of buoyancy and mechanical power transmission.

How it works step by step:

- Strategic installation:

- Polypropylene (PP) float resistant to chemical corrosion

- PVC cable with IP68 protection rating for corrosive environments

- قابلیت Capable of being suspended up to 40 meters below the liquid surfaceتعلیق تا 40 متر زیر سطح مایع

- Automatic level detection

- Switching mechanism:

- A metal ball moving smoothly on an inclined surface

- High-precision SPDT contact actuation

- Automatic return system with level reduction

5 unique competitive advantages:

- Energy saving: completely passive operation (no electricity)

- Hydrostatic pressure tolerance: stable performance at 4 bar pressure

- Zero maintenance: no need for calibration after installation

- Ultra-fast response: Fast response time at temperatures from 0°C to 50°C

- Multi-fluid compatibility: water, acids, oils, concentrated wastewater

Table of vital parameters:

| Component | Technical Specifications | Competitive Advantage |

| Main body | PP + PVC | Permanent leak-proof sealing |

| Control ball | Polished 316L steel | Mechanical life 10+ years |

| Activation angle | 45° ±2° | High accuracy in viscous fluids |

Critical applications in industries:

- Petrochemicals: Preventing acid tank overflows

- Treatment plants: Pumping control in collection wells

- Modern Agriculture: Level Management in Liquid Fertilizer Tanks

- Food industry: Monitoring vegetable oil tanks

- Food industry: Monitoring vegetable oil tanks

Golden maintenance tips:

“For optimal performance in viscous fluids, pressure wash the float monthly. In severely acidic environments, use models with PVDF cable.”

PLS 20-10 Level Switch Expert Installation Guide | Multi-point configuration in deep tanks

Installation instructions

Strategic implementation steps:

- Determining the critical point:

- Accurate height detection for switch activation (depending on the need for full/empty control or alarms)

- Calculation of PVC cable length considering hydrostatic pressure up to a depth of 40 meters

- Cable implementation:

5 Golden Principles for Safe Installation

- Cable preparation:

- Using A2K anti-penetration gland to pass cables through the walls of metal tanks

- Apply 180° bends with a min radius of 10cm to prevent tearing.

- Electrical settings:

- Connection to a stabilized power supply of 24V AC ±10%

- Installing a 0.5A fast-acting protective fuse in the control circuit

- Buoyancy optimization:

- Maintain a minimum distance of 30cm from the tank walls.

- Avoid installation in the path of eddy currents.

Advanced Configurations Table

NAdvantage

2

Deep well pumping management

| Scenario | umber of devices | Special application | |

| Single-step control | 1 | Preventing overflow of concrete tanks | Reduce costs by 40% |

| Two-point s | ystem | Preventing pump running | dry |

Solutions to common challenges

Challenge: Level fluctuations in pressure vessels

Solution:

- Installing a hydraulic damper next to the float

- Using stainless steel counterweight (optional)

Challenge: Sediment formation in mineral fluids

Solution:

- Periodic service planning every 6 months

- And finally, this product is not suitable for highly turbulent fluids that are likely to be impacted and broken.

Technical specifications and materials of parts:

l MPolyprCSPb

| pressure | Working Pressure |

4 bar |

| working temperature | Working Temperature |

0-50 ˚C |

| The lowest density | Min. Density |

0.65 g/cm3 |

| The highest viscosity | Max. Viscosity |

400 cSt |

| Switching range when the ball is raised | Switch Rang of Ball Rising |

90˚ |

| Switching range when the ball is lowered | Switch Rang of Ball Falling |

45˚ |

| Bal | aterial | opylene |

| Cable and Gland Cable Material | PVC | |

| Shot Material | ||

| Sinker Material | ||

| Capacity of switches | Switch Capacity |

3A 24VAC |

| Cable length | Cable length |

3,6,10,15,20m& make to order |

Reviews

There are no reviews yet.