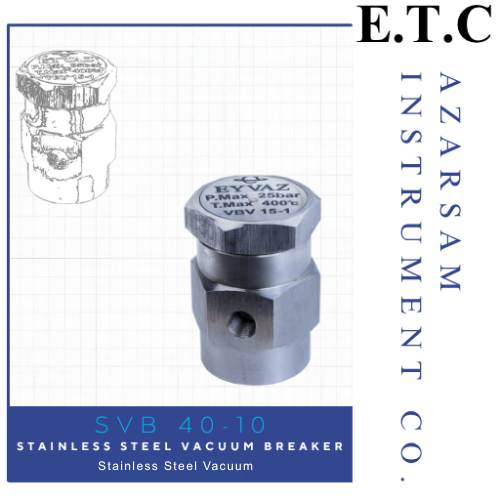

Vacuum Breaker | Vacuum Breaker | Stainless Steel Vacuum Breaker SVB 40-10

خلاء شکن | وکیوم بریکر مدل SVB 40-10 یک تجهیز کلیدی و حیاتی برای محافظت از سیستمهای لولهکشی و مخازن در برابر اثرات مخرب ناشی از ایجاد خلاء است. این دستگاه با عملکردی هوشمندانه، از تغییر حالت فیزیکی سیالات و بروز آسیبهای جدی به تجهیزات جلوگیری میکند.

Contact us for pricing and expert advice.

Vacuum Breaker SVB 40-10 | System protector against destructive vacuum

Vacuum Breaker | The SVB 40-10 vacuum breaker is a key and vital piece of equipment for protecting piping systems and tanks from the destructive effects of vacuum. This device, with its intelligent operation, prevents the physical state of fluids from changing and serious damage to equipment.

Technical features and key benefits:

- Reliable protection: This vacuum breaker prevents deformation of parts and heavy financial losses by eliminating the vacuum created in the pipeline or tank.

- Reliable protection: This vacuum breaker prevents deformation of parts and heavy financial losses by eliminating the vacuum created in the pipeline or tank.

- Installation flexibility: Equipped with a standard threaded connection in two types: BSP and NPT with a size of 1/2 inch, it allows for easy installation and quick replacement in a variety of systems.

- Wide Application: This vacuum breaker is effectively used in oil and gas, petrochemical, power plants, steam systems, hot water systems, and food and pharmaceutical industries.

Critical applications of vacuum breakers:

This device is an indispensable safety shield for the following:

- Preventing vacuum caused by sudden fluid discharge or pumping stoppage

- Protecting storage tanks during emptying or flushing

- Prevents air from being sucked into the system and contaminating the fluid.

- Maintaining the mechanical integrity of pipelines and tanks

By choosing the SVB 40-10 vacuum breaker, you are making a safe investment to increase safety, reduce maintenance costs, and ensure the longevity of your equipment.

Vacuum Breaker Operation Mechanism | How to Prevent System Destruction

How does a vacuum breaker protect your system? In fluid transfer systems and storage tanks, vacuum (negative pressure) can sometimes occur due to reasons such as sudden pump shutdown or emptying operations. This phenomenon not only disrupts the normal flow of fluid and reduces efficiency but can also cause permanent deformation of tanks and pipes by exerting destructive inward forces.

As a smart protector, the vacuum breaker prevents all these problems from occurring by identifying and eliminating this vacuum.

How a vacuum breaker works in simple terms:

The operation of this safety valve is based on a simple and very effective principle:

- Normal mode (pressure balance): Under normal conditions, when the pressure inside and outside the system is in balance, a ball (or one-way valve) completely blocks the path by sitting on its seat and prevents any contamination from entering the system.

- Vacuum detection (valve opening): As soon as a vacuum or negative pressure is created inside the system, this negative pressure causes the ball to be sucked upwards and separated from its seat. This creates a path for outside air to enter the system.

- Vacuum release and return to equilibrium: Air flows from the outside environment to the point where the vacuum was created, rapidly increasing the pressure inside. When the pressure on both sides of the system is again in equilibrium, the weight of the ball (or a spring) causes the valve to automatically close, blocking the path again.

Applications of this protective device:

This vital equipment is used in a wide range of industries, including:

- Storage tanks for various liquids and fluids

- Boilers and boiler feed lines

- Condensate drain lines in steam systems

- Charging and discharging lines for expansion sources and pressure vessels

- Plumbing systems at risk of collapse

By installing a vacuum breaker valve, you can ensure the continuous and safe operation of your system and avoid repair costs and production line downtime.

Vacuum Breaker Installation Guide | Ensuring Proper Operation of the Device

Proper installation of a vacuum breaker valve is the first and most critical step in ensuring optimal performance and uninterrupted protection of your system. Following installation principles will maximize the life of the device and its efficiency.

Key and mandatory conditions for installation:

- Position: This valve must be installed vertically and completely upright. Any angled or horizontal installation of the device can interfere with the operation of its internal mechanism (e.g., ball movement) and cause it to malfunction.

- Location: The vacuum breaker should be installed at the highest possible point in the system or tank. This allows the device to react most quickly and effectively once a vacuum is created.

- Connection direction: Note that the threaded connection of the device (either BSP or NPT type) must be such that the system side (vacuum creation location) is connected to the lower part of the valve and the free air (atmosphere) is connected to the upper outlet.

Important technical points before installation:

- Connection size: Make sure your system’s connection size matches the valve’s connection size (which is usually ½ inch).

- Sealing: To completely seal the threaded connection, be sure to use Teflon Tape or a special paste suitable for the system’s operating temperature (up to 400 degrees Celsius). Avoid using liquid sealants that may penetrate the valve.

- Accessibility for service: Install the device in a location that is easily accessible for periodic inspection and service.

Dangers of incorrect installation:

Failure to follow these simple principles can lead to incomplete device performance, failure to evacuate vacuum, leaks, and ultimately serious damage to the system.

– Technical specifications and materials of parts:

p; connection typeconnection type of input airPressure deference for opening valveMaximum operating temperatureworking temperaturebody material

| Size &am | Screwed 1/2″ (BSP,NPT) | |

| Size and | Screwed 3/8″ (BSP) | |

| Min. | 4.6 mmHg | |

| Maximum nominal pressure | Max working pressure | PN25 |

| Max | 400˚C | |

| Body | Material | AISI 304 |

| cap material | Cap Material | AISI 304 |

| Washer material | Gasket Material | AISI 304 |

| Washer material | Shot material | AISI 304 |

Reviews

There are no reviews yet.