What are the types of globe valves and in what conditions are each used?

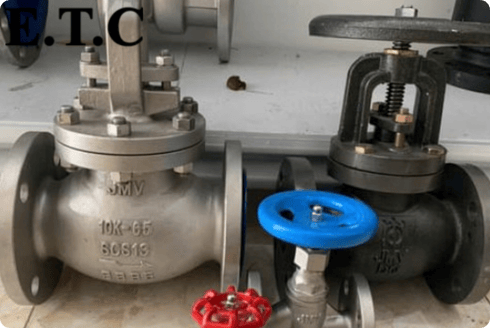

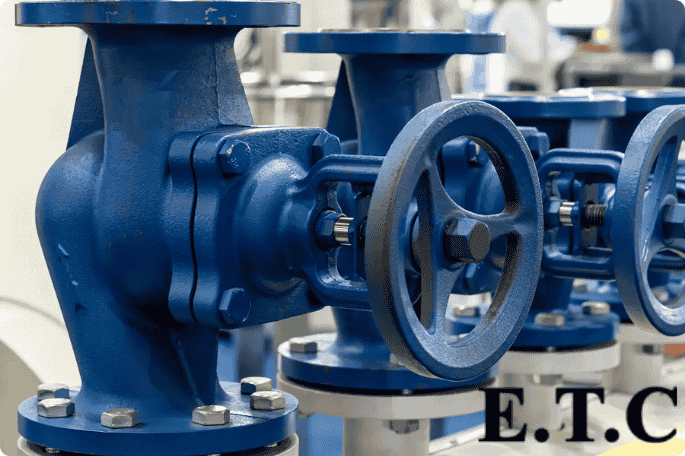

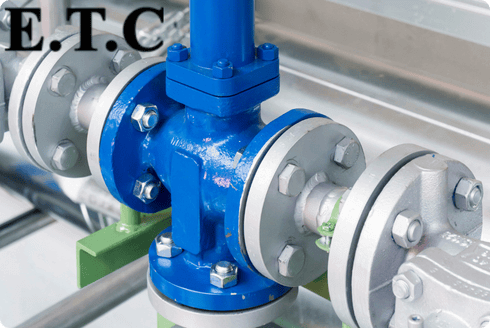

Globe valve types are primarily used to control fluid flow in pipelines and industrial systems. What is a globe valve? A globe valve is a key tool in every industry that is used as a control tool to precisely regulate the pressure of flows such as water, gas, steam, etc. A globe valve is a steam needle valve that has various types. The types of globe valves are as follows:

- Angle Globe Valve

- Angle Globe Valve

- Bellows Globe Valve

- Cryogenic Globe Valve

- Automatic Globe Valve

Types of globe valves based on bonnet and body

What is a globe valve? Globe valves, or spherical valves, are one of the most widely used industrial equipment. It is worth noting that the globe valve is a linear control valve that is On and Off. In the structure of the globe valve, there is a disc that can completely move away from the flow path or completely close it.

Globe valves are divided into three categories based on the type of connection, as follows:

1. Threaded bonnet ball valve

The threaded bonnet model is one of the simplest steam pressure relief valve models and is considered the cheapest globe valve. The bonnet model of the globe valve is suitable for spaces where pressure and temperature are high. In the bonnet model, the higher the pressure in the empty space above the body, the higher the other pressures applied and the better the sealing action.

2. Welded bonnet ball valve

Another type of globe valve is the welded bonnet globe valve. In this type of globe valve, as the name suggests, there is no need to open the valve. For this reason, it is used in various industries. It is worth noting that the weight of this model of pressure reducing valve with a welded connection is less than the weight of the screwed bonnet globe valve.

3. Screwed bonnet ball valve

The screwed bonnet model is the last series of globe valves based on the type of connection that we are going to discuss. Due to the screw connection, it is possible to open this globe valve and it is worth noting that it is easier to maintain than other models. This globe valve is used in industries for medium to high pressures.

What is the use of globe valves in various industries?

What is the use of a “globe valve”? Different types of needle valves have different uses in industries, depending on the type of material they are made of and their unique design. For example, the bodies of valves produced for low pressures are usually made of brass and bronze.Also, for high-pressure fluids, forged carbon steel or stainless steel are used. The said materials are for the body of different globe valves. While for the globe valve components such as the seat, disc and shaft, separate materials are used, according to the type and size of pressure.

The applications of globe valves in various industries are as follows:

- Oil and gas refineries

- Energy transmission lines

- Water, electricity and gas power plants

- Construction facilities

- Water and sewage

- Steam lines

- Lubrication systems

- Cooling towers

Ball valve components and parts

As mentioned, globe valves are made up of different parts. For this reason, “types of globe valves” are different from each other. Both in terms of structure and application. In the following, we will examine the components and parts of globe valves in the form of a table.

1.2.3.:4.is5.i6.7.

| Internal components | Description |

| Body | is manufactured in cast steel according to standards. Drain connections are available upon request. |

| The bonnet | is made of the same material as the body and the wall thickness is always greater than the standard requirement. |

| Disk | The disk is made of forged stainless steel and operates by rotating freely on the stem. |

| The seat ring | made of forged stainless steel with a minimum thickness of 12 mm and is welded to the valve body. |

| The stem | s stainless steel and machined from solid bars. The stem is connected to the disc by a major bearing ring. |

| Yoke | The yoke is individually constructed to resist drive thrust and the large compartments allow for easy ventilation of the enclosed space. |

| The actuator or drive (Hand Wheel) | comes in various types and is designed to provide easy operation of the valve. In some systems, it is essential for better performance in flow control. |

Advantages of ball valves

Ball valves have more advantages compared to gate valves. The main features of these valves compared to gate valves are that they open and close better and are more suitable for frequent opening and closing. Below we will explain the advantages of ball valves to you:

- Ability to properly disconnect and reconnect current

- Ability to maintain fluid flow

- Higher connection and disconnection speed than gate valve

- Easy maintenance

- Acts as a check valve if the disc is disconnected from the rod.

Types of globe valves based on their diameter

Globe valve types are categorized into various types based on their orifice, each of which has its own characteristics and uses. Below we will list some of the most common globe valve orifices for you. Globe valve orifices include:

Composite conduit: A heat and abrasion resistant metal tab is installed at the end of the conduit. For this reason, it is safe to use in systems where steam and hot water are present.

Ball Valve: Used in low-pressure, low-temperature systems. It usually performs poorly in flow control and is used only for on-off.

Needle groove: Due to its design, it provides better movement and impact. It also performs the sealing action properly due to its compliance and high contact point.

5 types: globe valve, support, linear, type, cascade and automatic.

3 types. Ball valve type: threaded bonnet, welded bonnet, and screwed bonnet.

In a ball valve, it acts as a check valve if the disc is disconnected from the stem.