What are the types of industrial check valves and what are the features of each?

Types of industrial check valves are essentially one-way valves. A control valve is used to prevent the backflow of fluid in piping systems and comes in different types. Each type of industrial check valve has a different application in different industries. Types of check valves or one-way valves include:

| Types of check valves | andfeatures |

| Flanged disc check valve | ,compact design and flanged installation |

| Swing check valve | :The disc is connected to a hinge and has low resistance to flow. |

| A check valve | has a spherical ball that closes the path in the event of reverse flow. |

| Lift check valve | :Disc movement in a vertical chamber and opening and closing with pressure difference |

| A two-way axial check valve | that opens and closes symmetrically and reduces back pressure. |

| Poppet check valve | uses a piston to control flow and withstand high pressures |

| Spring-loaded check valve | has an internal spring that helps it close faster. |

| Diaphragm check valve | has a flexible diaphragm to open and close the valve. |

| Angle check valve installed | at specific angles and reducing pressure drop |

Application of various types of industrial check valves

Industrial check valves are basically designed to allow flow through a container. In simple terms, flow enters from one side and exits from the other. One-way valves are activated by the pressure of the flow in the direction of fluid movement, opening the disc and allowing flow to pass.Also, if any fluid returns, the steam pressure relief valve automatically closes. The valve can close due to gravity on the disc or spring return force or a combination of the two. The applications of various industrial check valves are as follows:

- Flanged disc check valve: Water supply and oil and gas systems

- Swing check valve: horizontal and vertical pipelines, oil and petrochemical industry

- Ball check valve: water and wastewater industries, pump systems

- Lift check valve: steam systems, pipelines with high pressure fluid flow

- Double check valve: oil and gas pipelines, water and steam transmission lines

- Poppet Check Valve: Pipelines and precise flow control, hydraulic systems

- Spring Check Valve: Water Supply and Fluid Transfer Systems with Water Hammer

- Diaphragm check valve: chemical industries and corrosive environments

- Angled check valve: Special industries with angled installation

Examination and operation of industrial check valves

In different industries, various devices are used to prevent damage to equipment. The structure of many devices that are placed in lines and in the flow path is such that they prevent the flow from returning and, if such an event occurs, it closes the fluid path. Next, we will examine how each of the industrial check valves works.

1. Flanged disc check valve

One of the most widely used types of check valves is the disc-between-flange model. This type of check valve, due to its compact design, is very suitable for systems that are faced with space constraints. This type of check valve is very easy to install and it is also worth noting that it is light in weight. For this reason, this type of check valve is very popular among various industries.

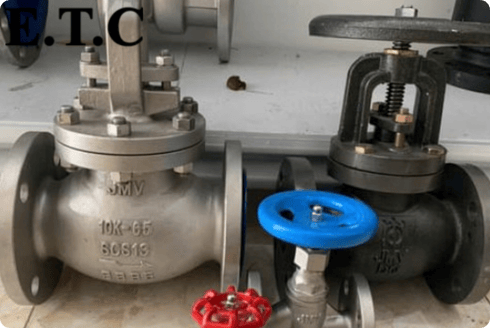

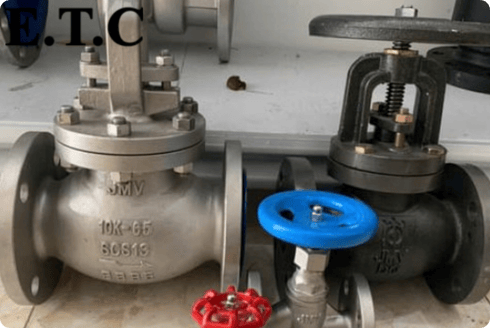

2. Swing check valve

Another “type of check valve” is the swing check valve, which reduces resistance to flow due to the free movement of the disc. This feature of the swing check valve allows the flow to pass through the system with minimal pressure. This is why the efficiency of the system is increased by using these check valves.

3. Ball check valve

This type of check valve, known as a ball check valve, uses a ball or tube as the opening mechanism. For example, when fluid enters the valve, the ball moves up and the steam needle valve opens. Conversely, when pressure decreases, the ball moves down and the fluid flow is cut off.

4. Check valve lift

In this type of check valve, a piston is used to open and close the pressure reducing valve. When the fluid flow goes under the piston and applies pressure to it, the piston in question rises and the valve opens. Also, as the pressure decreases, due to the weight of the piston and the force of gravity, the piston moves downward and the valve closes.

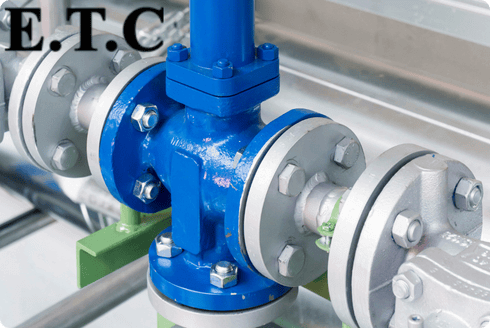

5. Double check valve

The double check valve has a special design. In this type of industrial check valve, two axial plates are used. These two plates open and close symmetrically and prevent impact or damage to the system.

6. Poppet check valve

Another name for poppet check valve is the silent check valve. These check valves have the ability to open and close very smoothly and do not make any impact. For this reason, they are noiseless and are called poppet check valves. This check valve is suitable for precise flow control due to its special internal parts.

7. Spring check valve

Another type of industrial check valve is the spring-operated check valve. This type of valve has a disc that is attached to a spring. When the valve inlet exceeds a certain limit, the spring opens and pushes the disc upward.

8. Diaphragm check valve

This type of industrial check valve has a flexible diaphragm that opens with fluid pressure and closes with pressure reduction or reverse flow. This type of check valve is suitable for corrosive fluids and suspended particles.

9. Angle check valve

Angle check valve is another “type of industrial check valve” that has a specific application. One of the advantages of installing an angle check valve is its use in confined spaces with a specific angle. These check valves help reduce pressure and increase system efficiency.

What are the advantages of industrial check valves?

What is a check valve? Check valves are essentially a one-way valve that prevents backflow. Their function is such that if the flow reverses, the valve automatically closes. Let’s look at the advantages of one-way valves. These advantages include:

- Prevent fluid backflow

- Withstands low to high pressures

- Use horizontally and vertically

- Automatic and automatic operation

- Prevent water hammer and damage to the system

- Mechanical operation without the need for electricity

- Lightweight and easy to install

- Low maintenance and repair costs

Industrial check valves essentially prevent backflow and close the valve when needed.

9 types, each designed to suit a specific space and use.

Diaphragm check valve is suitable for corrosive and chemically corrosive fluids.