What is a steam trap and what role does it play in steam systems?

What is a steam trap?

A steam trap is called a Steam Trap in English. After releasing its latent heat of vaporization in equipment, steam turns into condensate. Under certain conditions, part of the live steam may leave the equipment before it converts to condensate.How does a steam trap work?

The function of a steam trap is to prevent the escape of live steam. Therefore, it can be said that the steam trap is the last point where live steam is present. For this reason, in equipment that uses fluids such as steam, the presence of a steam trap is essential to ensure that condensate is discharged while preventing the loss of live steam.

Condensation in the control valve line can cause problems. These problems are as follows:

- Reducing the heat transfer level

- Reducing the heat transfer coefficient

- Corrosion in pipes

What is the main function of a steam trap?

What is the function of a steam trap (Steam Strap)? As you know, the steam trap is responsible for controlling steam condensation so that steam does not escape from the pipe in question. This tool is one of the most basic and essential tools in industrial processes that use steam. Next, we will examine the functions of a steam trap and explain them to you.

- Collect and discharge water vapor: A steam trap collects water vapor from plumbing systems and safely discharges it. This prevents pipe blockages, corrosion, and other problems.

- Maintaining system efficiency: The steam trap prevents the wastage of water vapor, and as a result, the system efficiency is well maintained and energy consumption is optimized.

- Preventing system hazards: By draining water vapor, the steam trap prevents other potential hazards such as explosions and burns caused by hot steam, making our system safer.

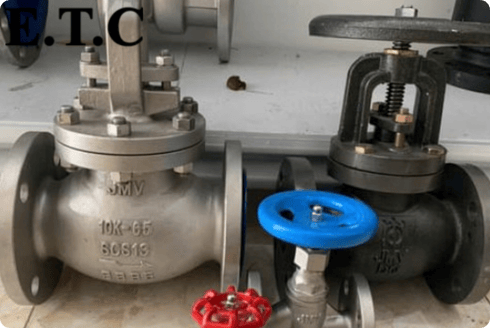

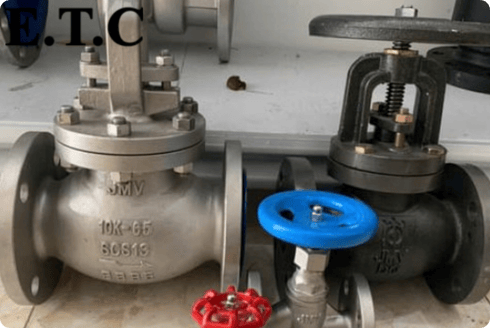

Types of steam traps

What are the types of steam traps? Steam traps are divided into 3 types based on the type of function, each of which has its own capabilities in different industries. It is also worth noting that each type of steam trap has its own advantages and disadvantages. Another point to note is their useful life under different operating conditions. Below we will examine the 3 most common types of steam traps.

Mechanical steam trap

The mechanical steam trap has a float that rises and falls according to the level of the condensate water and, through a mechanical connection, opens and closes the needle valve and controls the steam. A mechanical steam trap works based on the density difference between steam and water. As a result, other factors such as temperature or fluid velocity do not have a significant effect on these steam traps. Mechanical steam traps are among the most widely used types of traps, and the steam trap is installed near the condensate collection point. Also, the mechanical steam trap has several sub-categories, as follows:

1. Ball Float Mechanical Steam Trap

The main components of the traps are a floating ball, a lever, and an attached valve. When condensate enters the pipe, the said ball is immersed in the water and moves upwards.Finally, as the ball moves up, the main outlet valve of the trap opens, allowing condensate to escape from the trap. As a result, when steam enters, the ball falls down and closes the outlet valve, preventing steam from passing through. These types of traps are used for areas where the heat transfer rate is high and there is a flow of condensate attachments.

2. Inverted Bucket Mechanical Steam Trap

Bucket steam traps are used to account for the difference in specific gravity between condensate and steam. The way these traps work is that there is an inverted bucket inside the trap that, when condensate enters the trap, is submerged in water and falls to the bottom based on its weight.As a result, the trap opens to drain the condensate and when steam enters, it moves upwards and closes the trap outlet valve. The bucket steam trap has the ability to withstand very high pressure and another advantage of this type of trap is that it allows condensate to pass regardless of the fluid temperature.

Thermostatic steam trap

Another name for a thermostatic trap is a thermal trap, which operates on the temperature difference between the steam and the condensate. A thermal steam trap has a valve that moves back and forth due to temperature changes, expansion and contraction. Pressure reducing valves are designed to open only when the liquid temperature reaches a lower limit than the saturation temperature.This type of trap is suitable for industries where the condensate flow rate is low. These traps are made of steel or brass and can withstand pressures up to 50 bar. Thermostatic steam traps have 3 sub-categories as follows:

1. Liquid Expansion Thermostatic Steam Trap

This steam trap is for draining cold condensate when the system is completely shut down, and you should be careful that this steam trap is not suitable for temperatures above 100 degrees Celsius. The advantages of this steam trap include rapid air evacuation during startup.Liquid Expansion Steam Trap Due to its internal structure, if the pressure increases, its temperature also increases and for the same reason it cannot pass condensate well. The basis of this type of steam trap is a capsule containing a liquid that can contract, expand, and boil at a lower temperature than water.

2. Balanced Pressure Thermostatic Steam Trap

This type of trap, like the previous model, has a small capsule with a lower boiling point than water. When cold condensate enters the trap, the capsule contracts and opens the trap’s outlet valve, allowing the condensate to escape through the valve.Also, if steam enters, the capsule expands and prevents steam from escaping. This type of trap is manufactured in such a way that it also reacts to fluid pressure. So that as pressure, time and temperature increase, the function of the trap changes and adapts itself to the system. These traps are capable of withstanding temperatures up to 70 degrees Celsius.

3. Bimetallic thermostatic steam trap

This type of trap operates on the temperature difference between the condensate and the steam. They work by using two metals with different heat transfer coefficients welded together at both ends. What is the function of a steam trap? A bimetallic steam trap has a constant temperature response line that is used to match the saturation curve of two or more elements in a trap.When cold condensate enters the trap, the normally flat elements deform into a curved shape, causing the outlet valve trap to close. Its advantages include good air evacuation during start-up, resistance to hammer blow and corrosive condensate from high pressure steam.

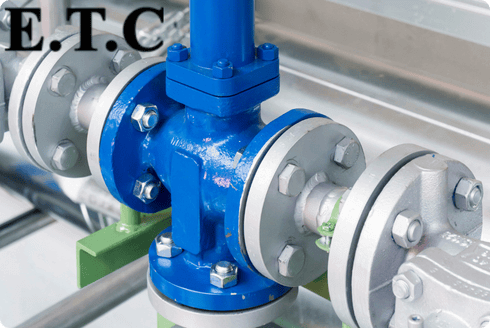

Thermodynamic steam trap

The thermodynamic steam trap works by using the property of fluid velocity. When a low-temperature fluid enters the valve, a movable disc located at the outlet end of the trap is submerged, preventing condensate from escaping.When the steam or condensate reaches a high temperature, due to the fluid passing through a bottleneck and increasing the speed of passage, some of the condensate turns into steam and a flash occurs. Due to the difference in cross-sectional area at the top and bottom of the disc, more downward force is applied to the disc, and as a result, the trap closes.

Important points when buying a steam trap

As you understand what a steam trap is, you should know that having a steam trap is essential in industries that use fluids such as steam. You should also pay attention to a number of points when purchasing to ensure you get the “best type of steam trap” for your industry. Below, we will examine the important points when purchasing a steam trap and explain each one to you.

- Importance of removing condensate from the system: Distilled water or condensate is a product of heat transfer from the steam system, which is created by radiation or heat transfer with the surrounding environment. However, distilled water that evaporates due to latent heat loss must be removed from the system quickly. This is because it causes the following problems:

– Water hammer due to the presence of condensate

– Reduction in the thermal efficiency of the system - The importance of reducing energy consumption: In addition to removing condensate, the steam trap also has other functions. It is also responsible for preventing steam from escaping, using maximum energy, and preventing energy waste.

- Removal of air and non-condensable gases: Air is naturally present in steam lines and industrial equipment. This existing air must be removed from the system. Because the existing air occupies part of the steam volume and reduces the temperature of the air and steam.

Benefits of using a steam trap

Benefits of using “What is a steam trap?” Choosing the right steam trap can bring many benefits to your equipment and industry. As you know, the steam trap is responsible for removing condensate from the pipe. Below, we will examine the benefits of steam traps in the form of a table.

::

| Advantages | Explanations |

| Increasing steam system efficiency | helps maintain steam system efficiency by preventing water vapor from being wasted. |

| Increasing system safety | by draining water vapor prevents potential hazards such as explosions, etc. |

| Cost reduction | Helps reduce energy costs by reducing steam consumption. |

| Corrosion Reduction | Helps reduce pipe corrosion by preventing water from accumulating in the plumbing system. |

Reduced heat transfer surface area, reduced heat transfer coefficient, and corrosion in pipes are some of the problems that occur in the absence of a steam trap.

A steam trap essentially allows condensate and unrelated gases to escape from pipelines.

There are 3 types of steam traps: mechanical, thermostatic, and thermodynamic.