What is CV in valve control and how is it calculated?

What is the flow coefficient (Cv) in a control valve?

The flow coefficient of a control valve, known as Cv, is a numerical value that determines the flow capacity of a valve. This number indicates the amount of fluid that can pass through the valve without difficulty when exposed to a pressure drop measured in PSI. PSI is equivalent to one pound per square inch.The Cv coefficient has a direct relationship with flow capacity—meaning the higher the Cv value, the greater the flow rate through the valve.

What is the valve flow coefficient (Cv)?

The flow coefficient, Cv, is expressed in gallons per minute (GPM) in the imperial system and liters per minute (LPM) in the metric system. This coefficient is one of the main and most important parameters in valve sizing.Simply put, the Cv flow coefficient helps designers and engineers in various industries select the appropriately sized valve so that all fluids—including liquids, gases, and steam—can pass through the pressure-reducing valve easily and at the desired pressure.The formula for calculating the Cv of a control valve (flow coefficient) is:CV=Q×SGΔPCV = Q \times \sqrt{\frac{SG}{\Delta P}}CV=Q×ΔPSGThe parameters involved in this formula are explained in the table below.

| Parameter | Description |

| Q | Flow rate in gallons per minute (GPM) |

| SG | Accurate fluid weight |

| ΔP | Pressure drop in pounds per square inch (PSI) |

What are the factors affecting CV in valve control?

What are the factors affecting CV in valve control? Various factors can affect and change the CV flow coefficient. As you can see, the CV flow coefficient indicates the capacity of fluid flow through a valve. The parameters that contribute to the CV flow coefficient are as follows:

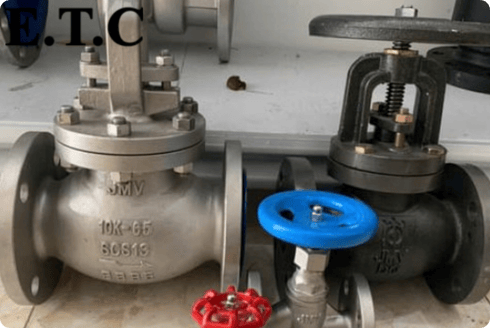

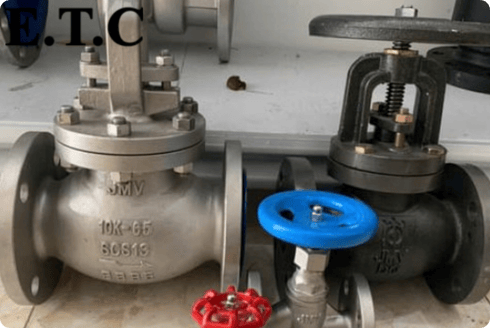

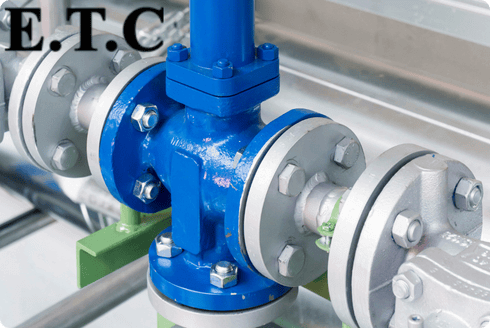

- Valve Size and Shape: The physical dimensions and appearance of a steam relief valve have a significant impact on flow capacity. As a result, larger valves with wider and more open passages have a higher CV flow coefficient because they allow for higher flow rates.

- Valve type: Different types of valves, such as globe valves, butterfly valves, ball valves, and plug valves, have different CV flow coefficients due to their specific design and features.

- Materials and Trim: Trim is essentially the internal components of the valve. It is worth noting that the materials used in the construction of the valve and its internal components change the

CV or flow coefficient in the valve control . For example, smooth surfaces and optimal trim improve flow efficiency and increase the CV coefficient. - Pressure Rating: The pressure rating of a valve determines its ability to withstand differential pressure. This parameter also has a significant impact on the CV flow coefficient.

- Temperature: The temperature of the desired fluid that is to be passed through the steam needle valve, because the temperature of the fluid affects its viscosity and, as a result, changes the CV flow coefficient.

- Flow characteristics: The flow characteristics of the fluid are another parameter that affects the CV flow coefficient. Flow characteristics refer to whether the flow is smooth or turbulent.

What are the variables of the valve flow coefficient (CV)?

As you understand what cv is in valve control, the formula for the flow coefficient CV is as follows: Cv=Q*√(SG/ΔP)

We are going to explain each of these variables in detail below. Because when calculating the valve flow coefficient CV, we need to know certain aspects about the fluid, such as the valve and the amount of fluid passing through the valve. The CV flow coefficient variables are as follows:

specific weight

Specific gravity refers to the exact weight of a fluid. It is denoted by the symbol SG. Specific gravity (SG) is the ratio of the weight of the fluid to the weight of water at 62 degrees Fahrenheit. The most obvious example of this variable is water, which has a specific gravity of 1.00. Ultimately, a denser fluid has a higher ratio, while a less dense fluid has a lower ratio.

For example, hydraulic oil weighs 0.8 grams per milliliter, and as we mentioned above, water weighs 1 gram per milliliter. So when hydraulic oil weighs 0.8 grams, it means that it is much less than water. If you can find the weight of any liquid in grams per milliliter, you can easily calculate the final specific gravity of the fluid.

Flow rate

Flow rate is represented by the symbol Q and is the amount of fluid that passes through the valve in a given time period. This value is usually expressed in GPM. To calculate flow, we need to have 2 parameters. The 2 parameters are volume (V) and time (T) which are necessary to calculate the flow rate.

Engineers divide Q by T to find volume (V). For example, suppose we have 100 gallons of water and it takes 15 minutes to flow through the valve. The result is a flow rate of 6.66 GPM, where T is measured in seconds.

pressure drop

Pressure drop, denoted by the symbol P, is considered the most complex variable to calculate. For this reason, it is recommended to use charts to determine the pressure drop for specific types of pipes.If charts are not used, numerous variables must be known. These variables include pipe friction factor, pipe length, pipe diameter, fluid density, and flow velocity.Therefore, it is generally better to use a chart to calculate pressure drop in order to avoid complications.

For example, steel pipes come in various diameters and lengths, and engineering toolkits provide useful charts for them. These charts can also be used for pipes made from other materials such as copper and PVC. When using these charts, you only need to know the pipe type, internal diameter, and your flow rate. This way, there is no need to calculate all the previously mentioned variables.

Why is CV flow coefficient important in valve selection?

Why is calculating the Cv in a control valve important?Selecting a valve with an improper Cv (flow coefficient) can lead to flow limitations. Flow restriction causes pressure drop, reduces system efficiency, and prevents optimal performance. On the other hand, choosing a valve with an excessively high Cv increases energy consumption and may damage valve components.Therefore, the appropriate Cv value must be determined based on the desired flow rate, pressure drop, and fluid characteristics.

In pipeline design, Cv flow-coefficient parameters are used to calculate valve pressure drop and determine flow rate. Experienced engineers in various industries use Cv values to optimize systems and ensure proper valve sizing. Valve manufacturers typically provide the Cv value so that engineers can refer to it during industrial processes and avoid spending time calculating Cv themselves.

The importance of differential pressure and valve size

Differential pressure is essentially the difference between the inlet and outlet pressure of a valve. This factor is one of the most important parameters in determining a valve’s Cv and calculating its flow capacity. By measuring the pressure difference between the inlet and outlet, engineers in various industries can easily calculate the appropriate valve size and flow capacity.This helps them optimize their systems in the best possible way and prevent potential problems. By calculating fluid pressure, engineers can perform the following tasks:

- Accurate valve measurement for pressure drop and flow rate

- Preventing flow choke or insufficient flow capacity

- Optimizing valve performance in various industries

The effect of correct and incorrect sizing of the control valve

What is control valve sizing?Selecting the proper valve size is essential for optimal system performance, and flow capacity plays a very important role in determining valve size. Flow capacity refers to the maximum amount of fluid that can pass through a valve without causing any problems.By calculating the control valve flow coefficient (Cv), the pressure drop and fluid density are also determined. Therefore, to achieve a specific flow rate and pressure drop, engineers must correctly select the appropriate valve size.

If the valve is sized incorrectly, the flow capacity becomes restricted, leading to pressure drop throughout the system. As a result, the system’s performance becomes suboptimal and weakened. In some cases, improper sizing may even cause damage to other valve components.Therefore, selecting the correct valve size is essential for optimal system performance and proper functionality. This helps prevent potential issues and avoids unnecessary costs.

Advantages of using CV in valve control

Using “CV flow coefficient in valve control” has many advantages, the most important of which are optimal system performance and no damage to other components. With CV in various industries, we can be sure of the parameters affecting each valve. The advantages of using CV flow are as follows:

- Accurate selection of valves

- Improved control system stability

- Optimizing energy consumption

- Increasing the useful life of equipment

The formula for calculating CV is Cv=Q*√(SG/ΔP)

Valve shape, valve type, materials of construction and internal components, pressure rating, temperature, and flow characteristics are all factors that affect the CV coefficient.

The exact weight of the fluid, the flow rate, and the inlet and outlet pressure drop are among the values necessary to calculate the CV flow coefficient.